High functional

plant-based bioplastics

PlaX™ can solve the major issues surrounding petroleum-based plastics, such as the generation of large amounts of CO2 emissions during incineration, and accumulation in landfills since they do not naturally break down. In addition, issues faced by conventional polylactic acids and other bioplastics, such as heat resistance and transparency, have also been resolved, as well as improvements in processing and formability. Processing can be carried out using the same manufacturing line as that previously used for plastics.

Feature

Various performances and functions have been updated, further expanding the application range

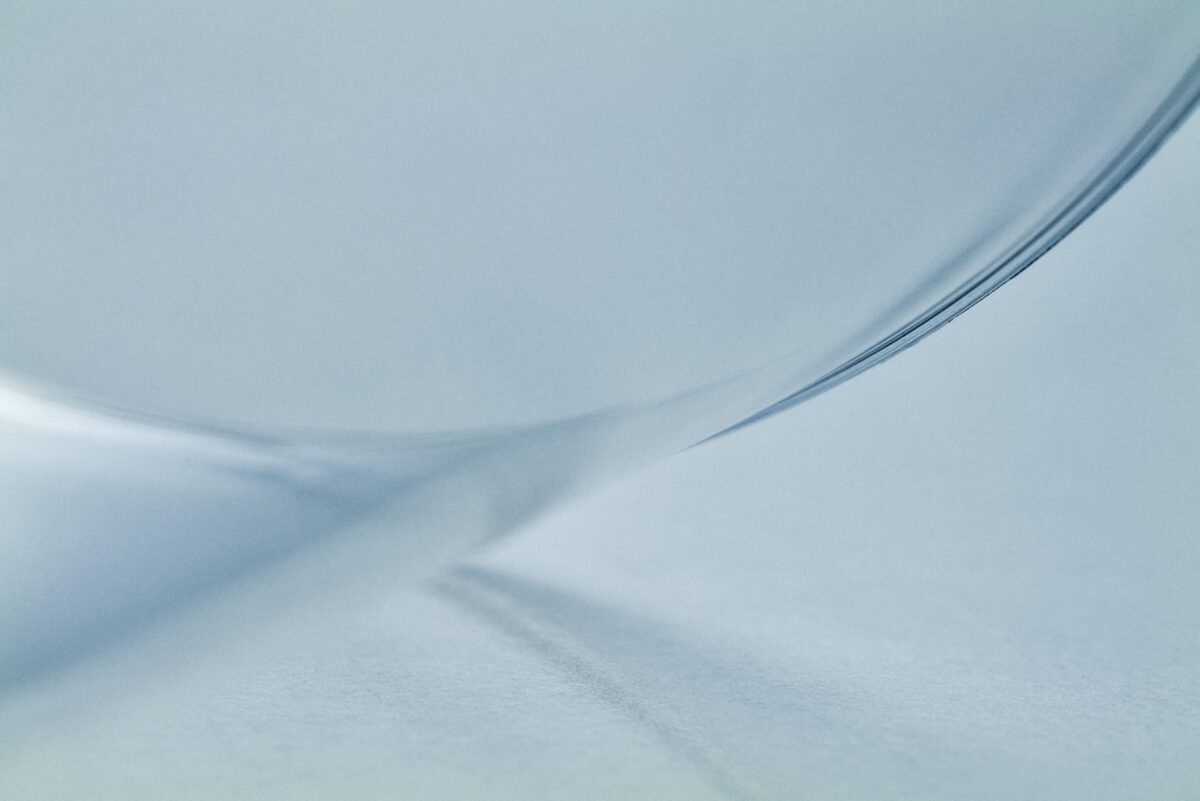

Transparency and heat resistance have been significantly improved

PlaX™ has greater heat resistance at 140℃, compared to that of conventional polylactic acid (approx. 50℃) and at the same time, better transparency was also achieved. While maintaining transparency, PlaX™ can be used over a wide range of applications, including lids for cups and bottles which require high heat resistance.

Improved heat resistance. Longer durability

Durability of PlaX™ has been greatly improved compared to polylactic acid. When conventional polylactic acid first hit the market, it was mainly used for disposable applications due to its limited durability. PlaX™ however has an added durability of 7-10 years. Use in applications which were previously unattainable is now possible.

The molding cycle is the same as general-purpose resins

Significantly improved crystallization speed has made processing PlaX™ with the same molding cycle as general-purpose resins such as PP and PET possible. Since it can be formed in metal molds at water temperatures adjusted to 100°C or less, selection of a manufacturing site is not difficult.

Use Application

Pursuing possibilities

Before commercialization of a customized PlaX™, creating a sample is essential. We pursue the possibilities along with the client, such as the kind of application, what functionalities are needed, etc. Please feel free to contact us.

Production Technique

Manufacturing lines used for conventional plastic molding, such as blow molding, injection molding, and sheet molding, can be used.

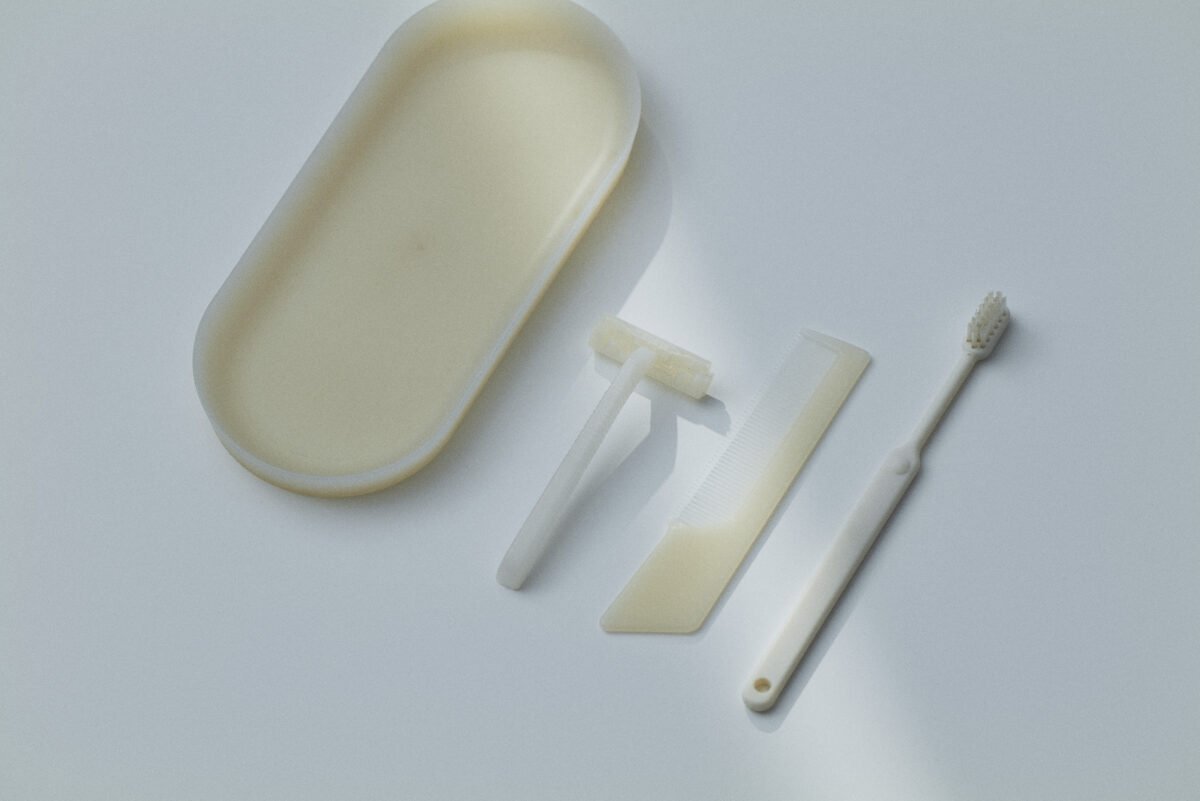

Case Studies

Collaboration with brands and manufacturers

Original PlaX™ resin molding products can be developed by adjusting the modifier components to suit the application requirements such as strength, heat resistance, etc.

Beer cups

Injection molding. PlaX™ was used at RISING SUN ROCK FESTIVAL 2022 in EZO, the first case in Japan to introduce bioplastic cups at a large music festival.

BIO TORSO

Blow molding. Nanasai Ltd. has adopted PlaX™ as a material for BIO TORSO, a plant-derived biodegradable body that is born from nature and returns to nature.